Highpower Ultrafast Lasers – We amplify your ideas!

We are a leading manufacturer of powerful ultrashort pulse lasers utilizing cutting-edge InnoSlab Technology. Our state-of-the-art lasers are commercially available with an impressive output power exceeding 600 W a pulse duration of 1 ps and pulse energy reaching up to 20 mJ. Features like 5,000 W burst-mode operation, low jitter, pulse on demand and high reprate operation are well established. Discover our new generation of highpower ultrafast lasersystems.

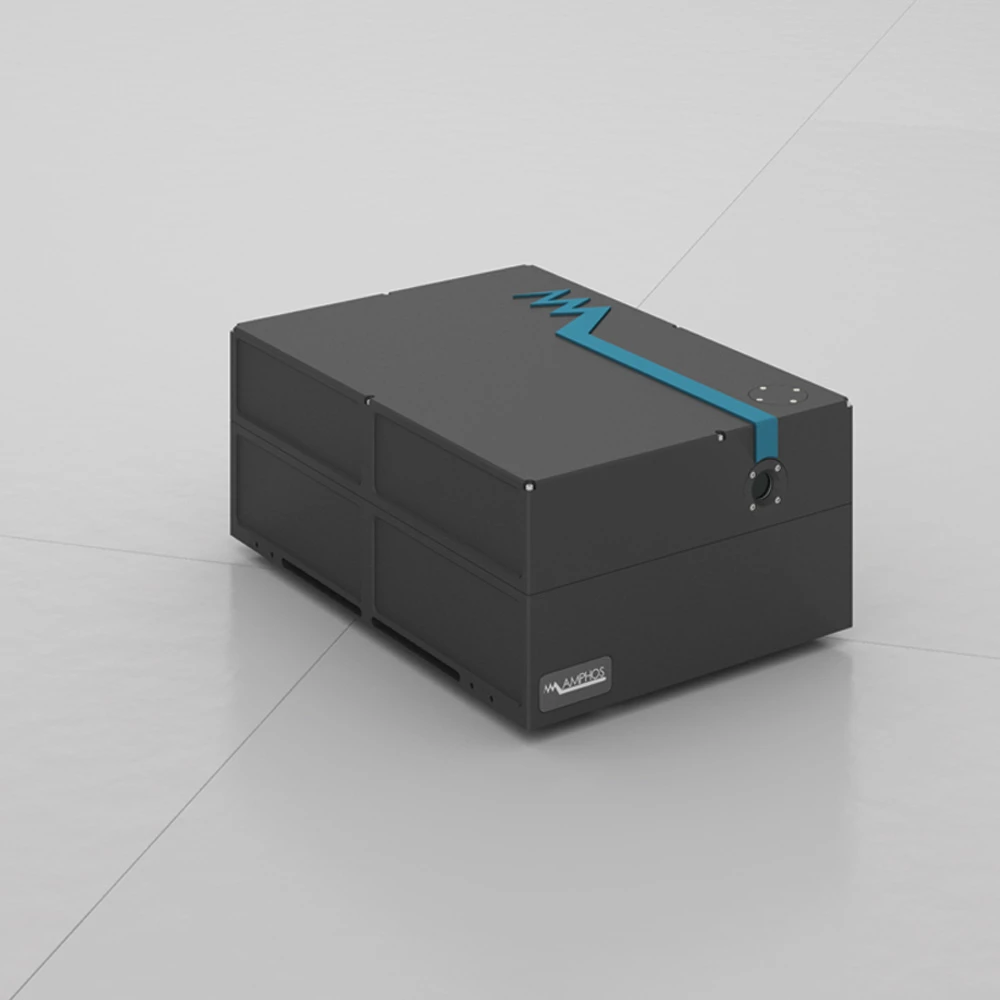

Modular design

Due to the modular design and the full vertical integration of all key components a very broad range of laser parameters can be addressed: customized lasers with high output power!

Compact & robust setup

Our new generation of amplifiers are designed as stable, reliable and robust OEM modules. The re-defined rigid testing and quality standards are bringing our new generation laser systems to the next level.

Flexible

The linear amplification architecture provides the highest flexibility. Repetition rates from single shot up to 40MHz or even GHz as well as tuneable pulse durations are standard and well appreciated features.

600 W

average power

20 mJ

pulse energy

< 1 ps

pulse duration

5 kW

in burst mode